| Designation: | RS30 9K57 Uragan |

|

|---|---|---|

| Manufacturer: | Splav State Research & Production Association FSUE | |

| Product type: | Weapons & Weapon Systems | |

| Name: | Multiple rocket launcher |

The system is designed to defeat manpower and materiel in concentration areas and also remotely lay antitank and antipersonnel mines in a combat zone at a distance of 10 to 35 km.

Components: launch vehicle, transloader, rockets, training facilities.

The system comprises the following types of rockets: 9M27F, 9M27K, 9M59, 9M27K2 and 9M27K3.

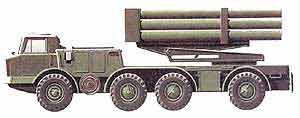

Like all Russian multiple rocket launcher (MRL) systems, the 220 mm BM 9P140 (16-round) Uragan (Hurricane) was developed under the guidance of the Splav Government Scientific Production Concern at Tula, which is to the east of Moscow.

While the overall prime contractor for the complete Urugan system is the Splav Scientific Production Concern, the actual launcher and transloader vehicles and associated equipment has been designed and built by the Motovilikha Plants Corporation based in Perm.

The system was designed in the early 1970s, with development being completed in 1975. It entered service with the Soviet Army in the same year and was allocated the STANAG designation of the M1977 by NATO, this being the year it was first identified.

The 220 mm BM 9P140 (16-round) replaced the older 240 mm (12-round) BM-24 and 200 mm (4-round) BMD-20 systems.

The complete BM 9P140 system has the industrial complex number of 9K57, which comprises the launcher, solid propellant unguided rockets and the essential rocket resupply vehicle. In the past the system has also sometimes been referred to as the BM-22 or BM-27.

Until the Splav 300 mm BM 9A52 (12-round) Smerch rocket system entered service with the Soviet Army in the early 1980s, the 220 mm 9P140 (16-round) was the largest system of its type in service.

The main advantage of the 220 mm BM 9P140 (16-round) launcher system is that it is mounted on a ZIL-135LM (8 × 8) chassis with improved tactical and strategic mobility.

Its rockets have a much longer range and carry a variety of warheads, enabling a wider range of battlefield missions to be undertaken using the same launch platform.

The Uragan was used in action during the Soviet occupation of Afghanistan and in Chechnya.

Until the introduction of the larger 300 mm BM 9A52 (12-round) Smerch system, the 220 mm BM 9P140 (40-round) was normally deployed in rocket artillery regiment and brigade formations at Army or Front (Military District) level.

In the case of the former, the regiment Table of Organisation and Equipment (TOE) normally comprises three battalions of 12 launchers, which is normally increased to 18 launchers in time of war.

In a Military District, an independent Uragan rocket artillery regiment has the same TOE. But if the Uragan unit is assigned to an artillery division within the Military District, then the unit may be either a regiment or brigade with four battalions each with 12 launchers (which would be increased to 18 in time of war). If the unit were already a brigade then it would take on the extra six launchers per battalion to achieve its wartime TOE.

Typical roles of the Uragan system would be to suppress enemy missile, artillery and mortar batteries as well as destroying strong points and other areas of resistance. It would normally use 'shoot and scoot' techniques to avoid counter battery fire.

In some units it has replaced the shorter-ranged 122 mm BM-21 (40-round) rocket system mounted on a 6 × 6 truck chassis. The Uragan has been designed to operate in temperatures ranging from -40 to +50°C.

The Uragan battalion is controlled by the Kapustnik-B automated fire-control system. This has a Battalion commander's vehicle based on the BTR-80 (8 × 8) APC chassis, a Battalion Chief of Staff vehicle based on the Ural-4320 (6 × 6) truck chassis, three Battery Commander's vehicles based on the BTR-80 APC chassis and three Battery Senior Officer's vehicles based on the Ural-4320 (6 × 6) truck chassis.

The Kapustnik-B comprises subsystems for reconnaissance, initial battalion orientation and location fixing, weather reconnaissance and ballistic tracking information, inter-battalion and higher echelon communication and data transfer. All the elements are connected to a single data processing computer.

If required, the system can automatically accept external reconnaissance data transfers and be connected to higher echelon automated control systems.

The system is based on a modified ZIL-135LM 8 × 8 truck chassis, which has excellent cross-country mobility and is used for a wide range of other battlefield missions. These include TEL (Transporter, Erector, Launcher) for the FROG-7 surface-to-surface unguided rocket system (and its associated reload vehicle), Sepal cruise missile carrier, cargo truck and tractor truck, to name but a few.

The chassis was developed at the Likhachev Motor Vehicle Plant near Moscow but production was undertaken at the Bryansk Automobile Works, for which reason the family is sometimes referred to as the BAZ-135L4.

The fully enclosed unarmoured crew compartment is at the front with the two diesel engines to the rear. The turntable-mounted rocket launcher is mounted at the very rear of the chassis and is traversed to the front for travelling.

The rocket launcher pod consists of an upper layer of four tubes and two lower layers of six tubes so giving a total of 16 launch tubes. The sighting system is mounted on the left side of the launcher and access to this is via a folding ladder.

The crew compartment accommodates the launch preparation and firing equipment and the operator can select single rockets or salvo firing. It is not fitted with an NBC system and as far as it is known does not have a land navigation system.

Steering is power assisted on the front and rear axles and a central tyre-pressure system is fitted as standard. This allows the driver to adjust the tyre pressure to suit the terrain being crossed without leaving his seat.

The ZIL-135LM cross-country vehicle is powered by two diesel engines each of which drive the four wheels on one side of the vehicle.

When deployed in the firing position, steel shutters are normally raised over the front windscreens and two stabilisers are lowered at the very rear to provide a more stable firing platform.

The launcher is mounted on a turntable at the rear with powered elevation from 0 to +55° and powered traverse of 30° left and right.

There is also a 9M27K fragmentation sub-munition cargo warhead rocket that weighs 270 kg and has a minimum range of 10 km and a maximum range of 35 km. It has 30 fragmentation sub-munitions.

The PGMDM scatterable anti-tank mine is also used in a number of other applications and consists of a liquid explosive charge contained in a thin flexible cover. It uses a pressure-activated fuze, which is also used in the PFM-1 anti-personnel mine.

Unconfirmed reports indicate that there was a chemical rocket for this system and RFAS reports state that a Fuel-Air Explosive (FAE) submunition rocket is also available.

The 9M59 220 mm rocket carries nine anti-tank mines and is 5.178 m long and weighs 270 kg. It is fitted with a warhead that weighs 89.5 kg with the nine anti-tank mines capable of covering an area of 250 hectares.

The anti-tank mines weigh 5 kg and are fitted with a proximity fuze. They carry a 1.85 kg explosive direction charge which has a high armour-piercing capability. The mines have a self-destruct time of 16 to 24 hours.

The 9M27K2 rocket has a 89.5 kg cluster warhead carrying 24 anti-tank mines which cover an area of 150 hectares. The PTM-1 mines have been designed to destroy the tracks of tanks and other armoured vehicles, rather than to pierce the armour of the vehicle.

These mines weigh 1.5 kg and are fitted with a 1.1 kg PW-12S high-explosive charge. The self-destruct fuze time of the PTM-1 anti-tank mine is 3 to 40 hours.

The rockets are fin and spin stabilised and have wraparound fins at the rear that unfold after the rockets are launched.

According to RFAS sources, each salvo has a destructive area of 20,000 to 460,000 m2. If the rockets are launched singly then one rocket is launched every 8.8 seconds. A complete salvo of 16 rockets takes 20 seconds to launch.

Maximum time quoted for the system to be prepared for action from the travelling configuration to ready to fire is 3 minutes with a similar time to come out of action.

Each BM 9P140 launcher is normally accompanied by at least one and sometimes two, 9T452 transloader vehicles based on the same ZIL-135LM 8 × 8 chassis.

The transloader vehicle carries 16 reload rounds arranged in two stacks positioned one either side of the vehicle. Mounted to the immediate rear of the cab is a hydraulic crane operated by one person, which is used to resupply the rocket launcher. This crane has a maximum lifting weight of 300 kg with the operator being seated to the rear.

For reloading, the launcher has to be in the horizontal position and traversed to one side. The new rocket is then loaded into the tube via the crane and rammed home by the rammer. It is estimated that the reload time is 20 to 30 minutes, a long time when compared to the 227 mm US Lockheed Martin Missiles and Fire Control Multiple Launch Rocket System (MLRS).

|

||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|